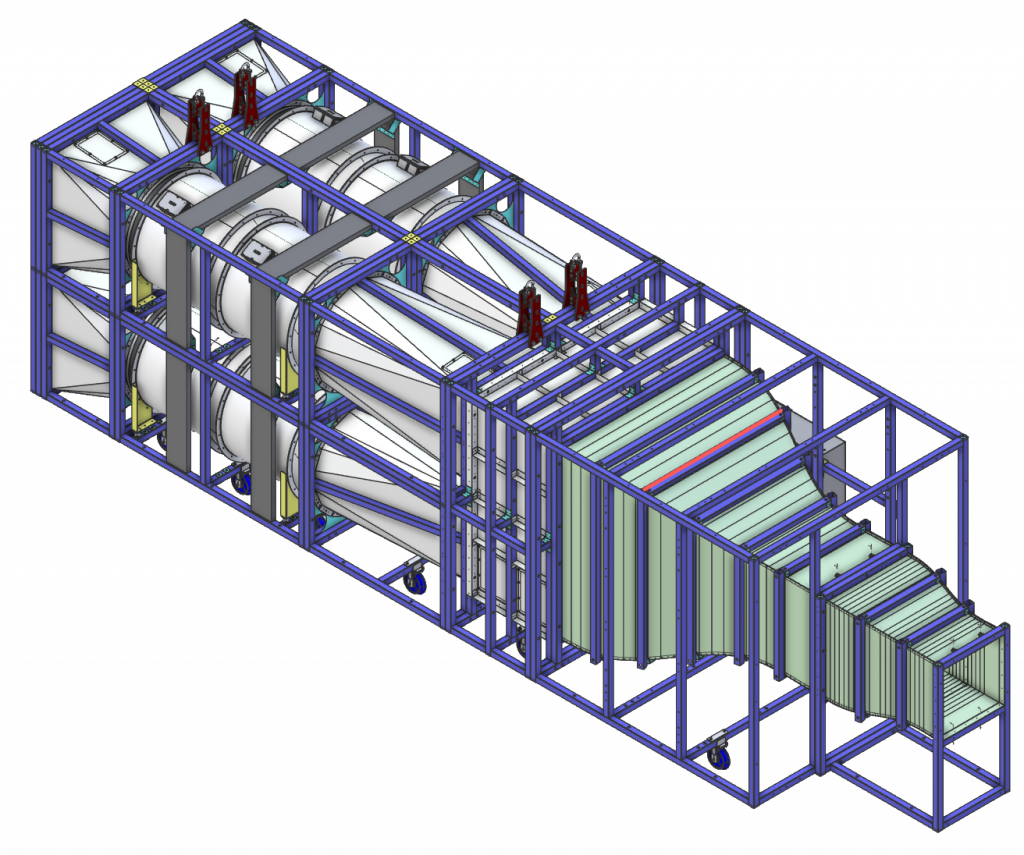

Reference project WT387

Fraunhofer

Highlights

|

Product Description

Basic Design

The WT387 consists of a welded steel profile construction and galvanized sheet metal. It is delivered in segments, which simplifies on-site assembly by our engineers. The special feature of the WT387 is that it is segmented into four smaller wind tunnels. These tunnels are connected to each other via a common nozzle.

Drive System

The WT387 is driven by eight vibration-isolated axial fans, two per wind tunnel segment. The nozzle and tail are designed to match the fans in order to generate a low-shear flow.

Flow Conditioning

Before the four wind tunnel segments are joined together in the nozzle, turbulence is prevented by screens. Furthermore, irregularities in the flow direction of the outflowing air are eliminated by honeycomb rectifiers. In the nozzle, the flow is further processed and any turbulence that may be present is suppressed.

Measurement

The measurement in the wind tunnel is taken at the end of the nozzle with a cross-section of 900 × 900 mm. By removing the first nozzle, the cross-section can be increased to 1200 × 1200 mm, but this results in a reduction in flow velocity.

Specification

| Design type | Eifel design, horizontal |

| Test cross-section | 900 x 900 (1200 x 1200) mm |

| max. speed | 80 m/s |

| Turbulence intensity | 2 % (@ 50% Speed) |