Reference project WT237

Ammonit Windtunnel GmbH

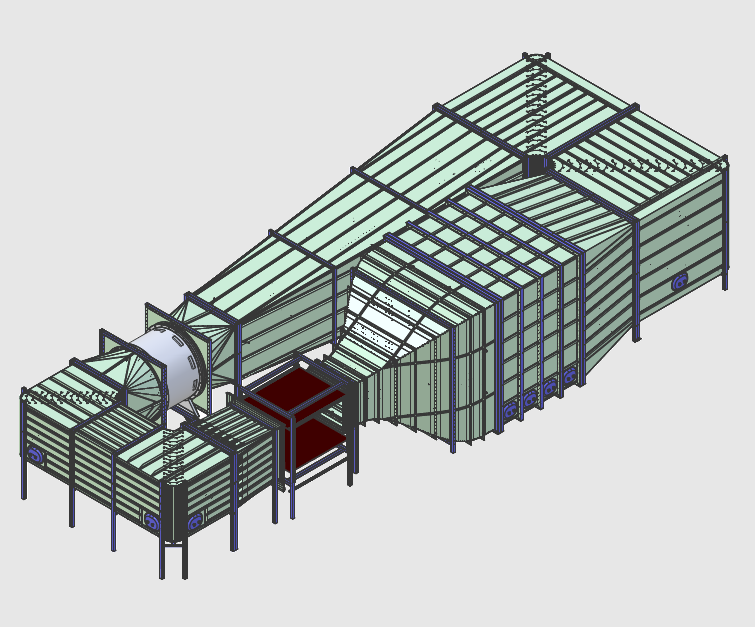

In Bargeshagen near Rostock, the WT237 wind tunnel was installed in the test laboratory of the company Ammonit Wind Tunnel GmbH. The wind tunnel is characterized by the low degree of turbulence, the high accuracy of the wind speed and the large test section with simultaneous high contraction and compact design. The WT237 forms the core of the laboratory accredited according to “DAkkS”, “measnet” and “DKD”.

Product description

Basic structure

The WT237 consists of a steel profile welded construction and galvanized sheet metal. The additional painting gives the wind tunnel an attractive appearance and is also protected against corrosion. Large manholes in all relevant segments make it easy to enter the inside of the wind tunnel.

Drive

The WT237 is driven by a vibration-decoupled axial fan. This is mounted on spring vibration dampers. The fan is connected to the wind tunnel via canvas flanges. This ensures low-noise plant operation.

Flow preparation

The WT237 has non-expanding corners. The sieve chamber contains four sieves at an optimal distance from one another. These non-split stainless steel sieves are accessible via manholes for easy cleaning; the sieves do not have to be dismantled for this purpose. A honeycomb straightener with a length-to-diameter ratio of 8: 1 further reduces the swirl of the flow. In a nozzle, the nozzle geometry of which corresponds to a polynomial of the fifth order, the flow is prepared and any turbulence that may be present is suppressed.

Measurement

The measurement in the wind tunnel takes place with the test section half open. A turn-swing unit for the multi-dimensional calibration of ultrasonic anemometers is installed in this test section. The test section has a flow collecting funnel to reduce the flow losses during the measurement. The recording of flow characteristics using optical measurement methods, e.g. PIV (Particle Image Velocimetry) or LDA (Laser Doppler Anemometry) is possible without any problems.

Highlights

The WT237 is equipped with a three-axis traverse. The wind tunnel is used to calibrate cup cross anamometers. For this purpose, the system must be operated almost continuously every working day.

Characteristics

| Design type | Closed loop, standing |

| Measuring cross section | 1200 x 1200 mm |

| Measuring length | 2000 mm |

| Top speed | 30 m/s |

| Turbulence level | 0,4 % |