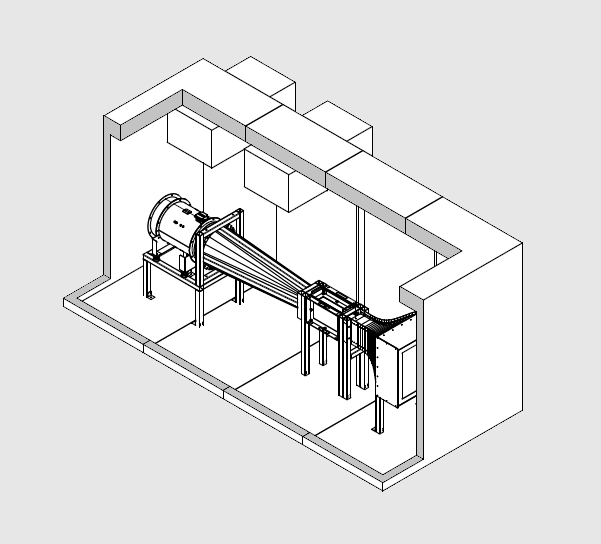

Reference project WT341E

Airbus Warsaw

The first ice wind tunnel of the Baltic Wind Tunnel – made entirely of stainless steel – cooled by two cooling units

|

|

|

The core of the WT341E ice wind tunnel is a wind tunnel based on the Eifel design. This is completely made of stainless steel (frame raw, sheet metal parts ground). This means that the WT341E is protected against the corrosion caused by condensation during cooling operation.

To suppress turbulence, the wind tunnel has a honeycomb rectifier in a honeycomb cassette, followed by three screens. These can be removed from the inflow tract for cleaning.

The nozzle with a contraction of 9 accelerates the flow in the 200 x 200 x 500 mm measuring chamber to up to 50 m/s (180 km/h).

The ingenious design of the diffuser enables the flow to be guided without detachment to the vibration-decoupled axial fan in the shortest possible space.The temperature of the air in the cold room in which the WT341E works is controlled by two Viessmann cooling units.

This makes it possible to carry out aerodynamic measurements in the temperature range from -25…40 °C.

The system is controlled centrally via the proven wind tunnel control system BWT-Control, comfortably via Touchpanel. |

Characteristics

| Design type | Eifel type |

| Measuring cross section | 200 x 200 mm |

| Measuring length | 500 mm |

| Top speed | 50 m/s |

| Turbulence | 0,5% @ 25 m/s |

| Datasheet WT341 |