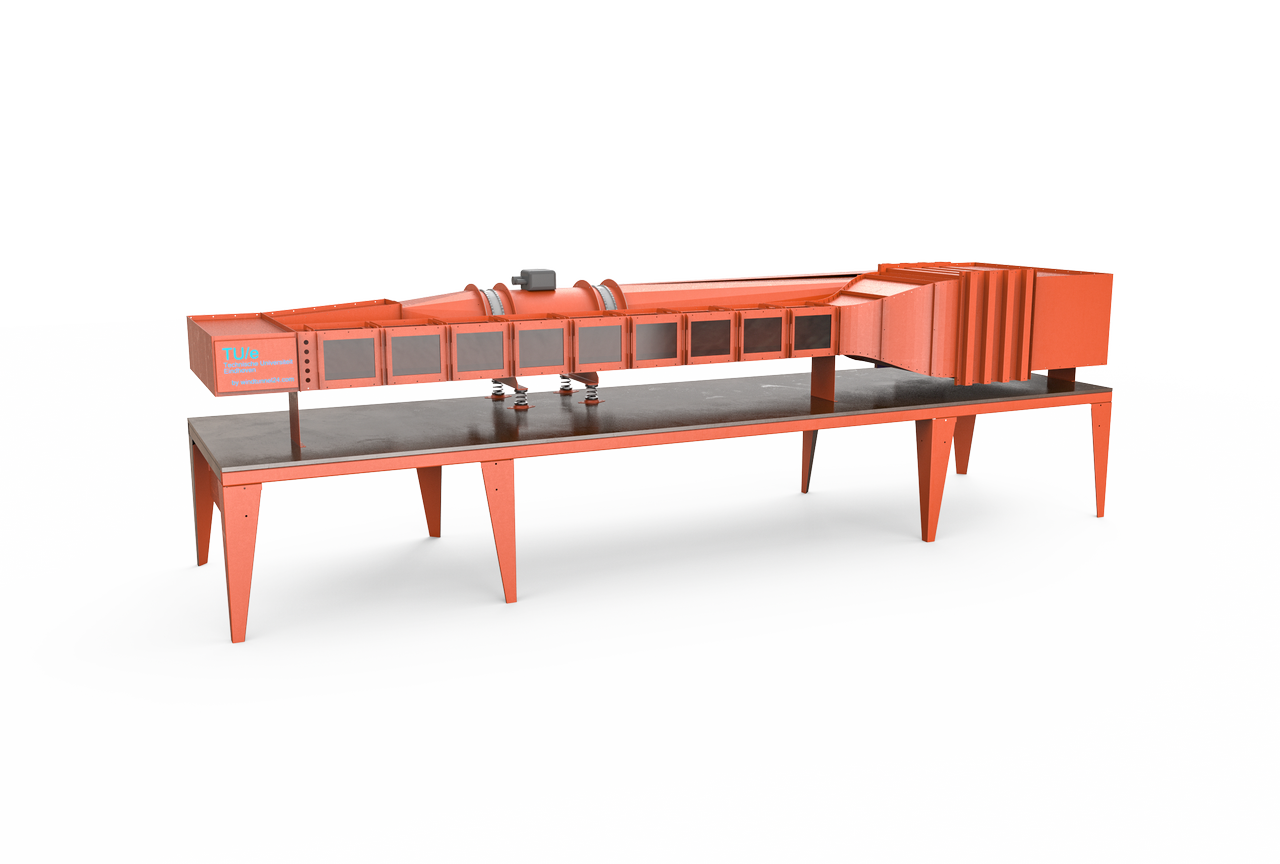

Reference project WT284

University of Eindhoven

The WT284 wind tunnel was built for the University of Eindhoven. The wind tunnel is used for boundary layer investigation and is characterized by a large measuring chamber, the expanding corners as well as the long diffuser and the low degree of turbulence.

Highlights

|

Product description

Basic structure

The WT284 consists of a steel profile welded construction and galvanized sheet metal. The additional painting gives the wind tunnel an attractive appearance and is also protected against corrosion.

Drive

The WT284 is driven by a vibration-decoupled axial fan. The fan, which is mounted on spring shock absorbers, is connected to the wind tunnel via canvas flanges. This ensures low-noise plant operation.

Flow preparation

The long diffuser, whose small opening angle counteracts flow separation, opens into the expanding large corners. The wind tunnel has a large sieve chamber. This contains three sieves at an optimal distance from one another. These non-split stainless steel sieves can be separated from the sieve chamber for easy cleaning. A honeycomb straightener with a length-to-diameter ratio of 8:1 further reduces the swirl of the flow. In a nozzle, the nozzle geometry of which corresponds to a polynomial of the fifth order, the flow is prepared and any turbulence that may be present is suppressed.

Measurement

The measurement in the wind tunnel takes place in the 3 meter long test section with a cross section of 200×300 millimeters.

Characteristics

| Design type | Closed loop, lying |

| Measurement cross section | 200 x 300 mm |

| Measurement length | 2700 mm |

| Top speed | 25 m/s in basic configuration, up to 45 m/s feasible |

| Turbulence level | 0,3 % |