Reference project WT307

Technical University of Cologne

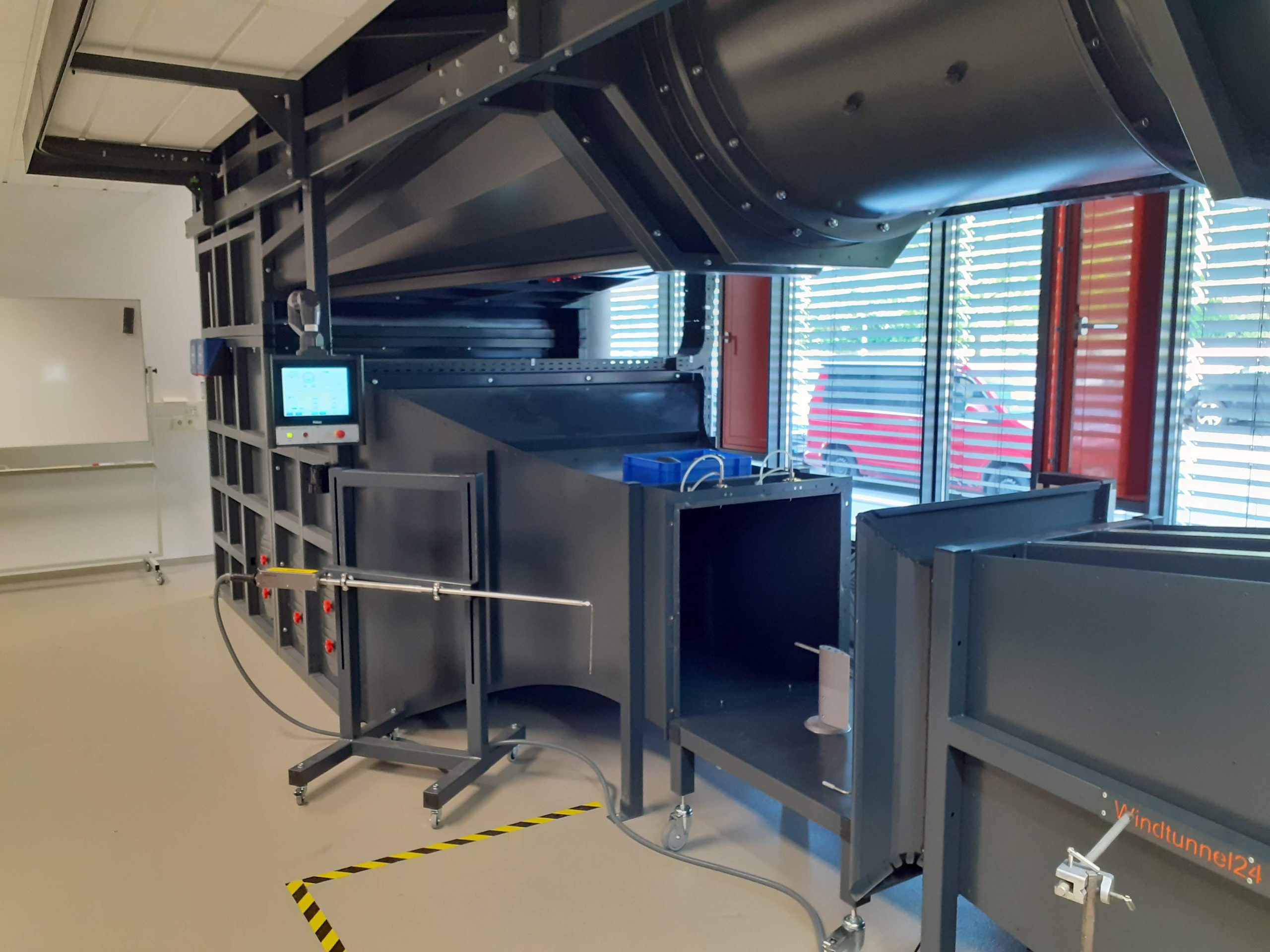

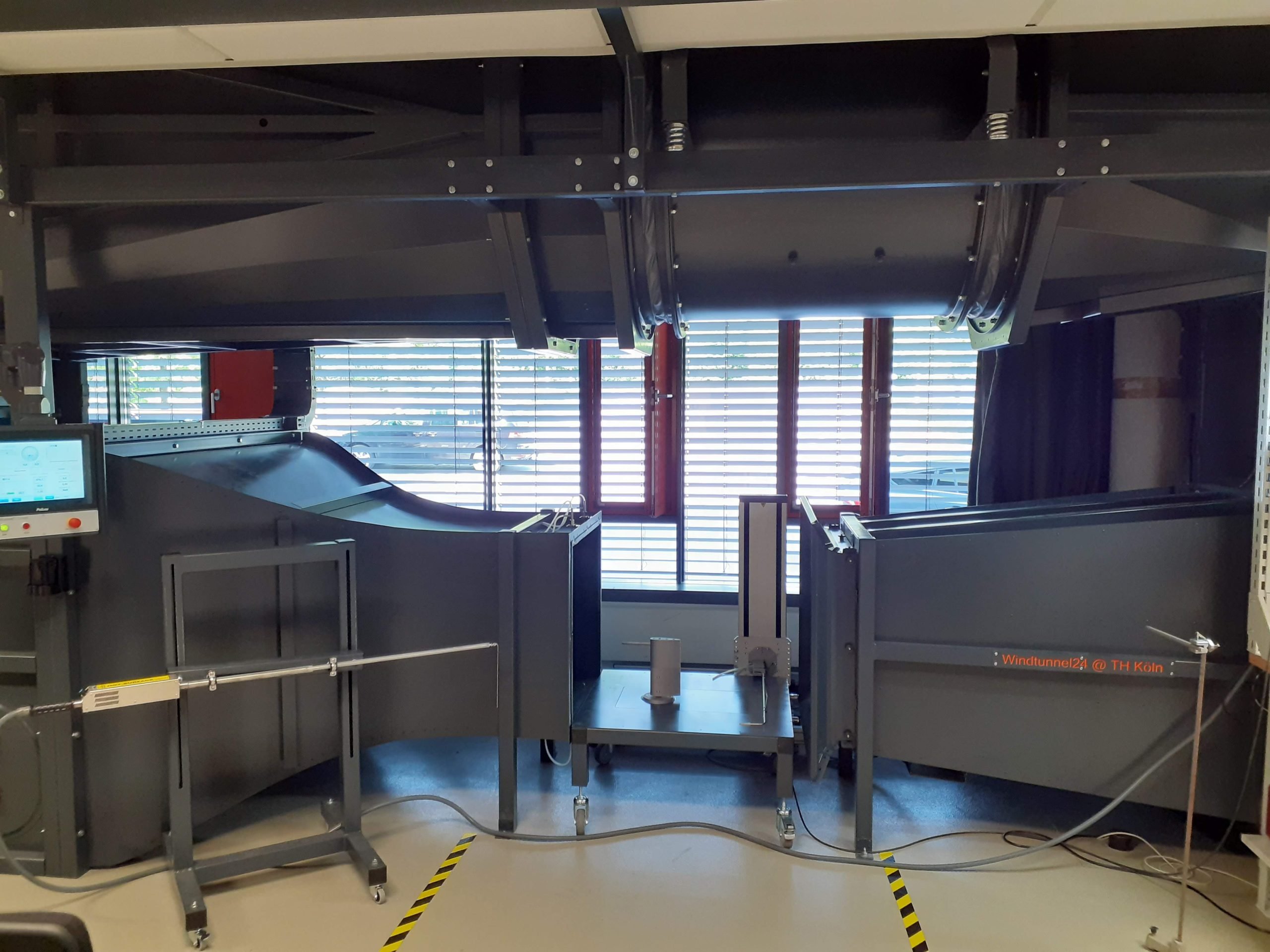

In cooperation with Prof. Dr.-Ing. Denis Anders, the WT307 wind tunnel was built at the TH Köln Gummersbach (contact: Markus Baum). The wind tunnel is characterized by its high performance combined with a compact design, the test section with a large measuring cross-section and the good freedom of movement in the area of the test section.

Highlights

|

Product description

Basic structure

The WT307 is made from a steel profile welded construction and galvanized sheet metal. The additional painting gives the wind tunnel an attractive appearance and protects it against corrosion. Large inspection manholes in all relevant segments make it easy to enter the inside of the wind tunnel.

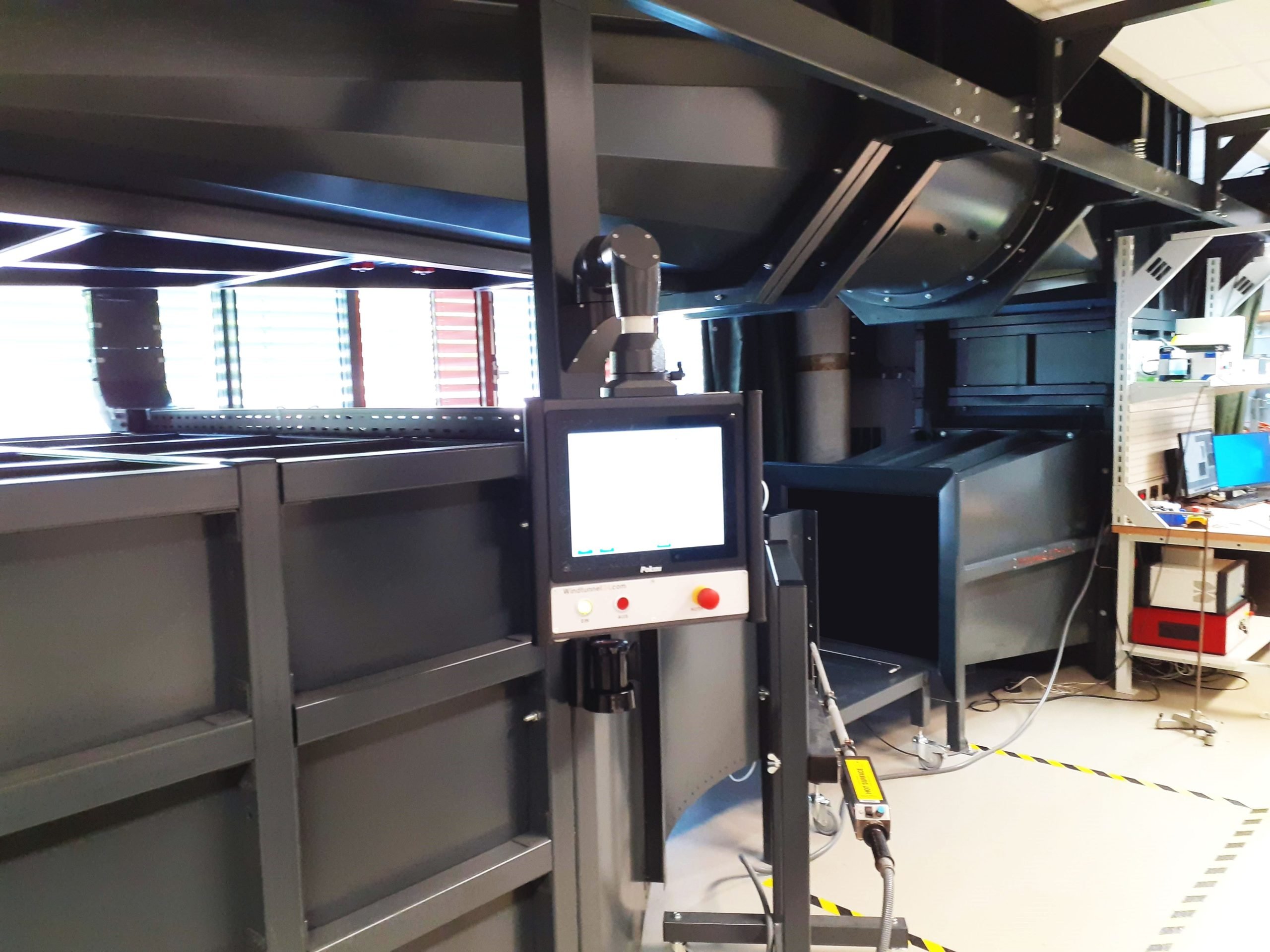

Drive

A vibration-decoupled axial fan drives the WT307. This fan is mounted, supported by spring vibration dampers, on a frame construction in the upper area of the wind tunnel. Since the frame construction works without vertical supports, there is excellent freedom of movement and work in the area of the test section. The fan is connected to the wind tunnel via flexible duct connectors. This ensures low-noise plant operation.

Flow preparation

The WT307 has non-expanding corners. The settling contains three screens with an optimal distance from one another. These non-split stainless steel screens are accessible via inspection manholes for easy cleaning. A honeycomb straightener with a length-diameter ratio of 8: 1 further reduces the swirl of the flow. In a nozzle, whose nozzle geometry corresponds to a fifth order polynomial, the flow is prepared and any turbulence that may be present is suppressed. The measurement in the wind tunnel can be carried out both with an open and with a closed measuring section.

Measurement

The measuring section can be converted ergonomically via a flange connection to the nozzle. Both the open and the closed measuring section can be equipped with a wind tunnel scale if required. The open measuring section has a flow collecting funnel to reduce the flow losses during the measurement. The inside of the closed test section can be seen through glass windows. The recording of flow characteristics using optical measuring methods, e.g. 2D-PIV (Particle Image Velocimetry) or 2D-LDA (Laser Doppler Anemometry) is possible without any problems.

Highlights

The wind tunnel was fitted into the limited room height of the university laboratory with an accuracy of a few centimeters. For a total length of 8.5m with contraction 5 and a measuring cross-section of 705x705mm, the limit of what is currently technically possible was reached. Optimal accessibility in the smallest of spaces is achieved by mounting the motor on a crossbar. The WT307 is equipped with a 24-channel pressure scanner and two wind tunnel scales with different measuring ranges. Furthermore, the wind tunnel is covered by a laser protection curtain, which means that work with the installed PIV and LDA system is possible without restricting the environment.

Characteristics

Closed test section

| Design type | Closed loop, standing |

| Measuring cross section | 705 x 705 mm |

| Measuring length | 1000 mm |

| Top speed | 58 m/s |

| Turbulence level | 0,4 % |

![]() Datasheet WT307 with closed test section

Datasheet WT307 with closed test section

Open test section

| Design type | Closed loop, standing |

| Measuring cross section | 705 x 705 mm |

| Measuring length | 900 mm |

| Top speed | 54 m/s |

| Turbulence level | 0,5 % |