Reference project WT327

University Rhein Main – Rüsselsheim

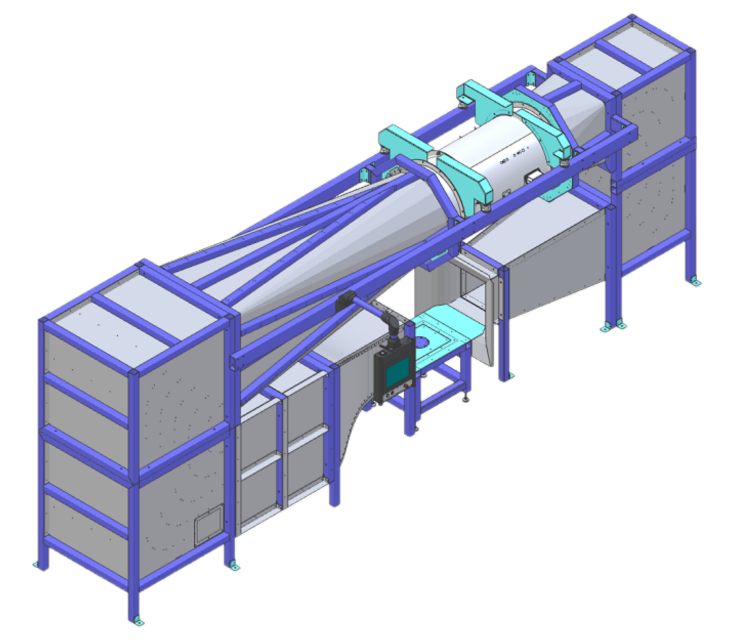

For the University Rhein Main (contact person: Prof. Dr.-Ing. Björn-Christian Will) the wind tunnel WT327 was built. The wind tunnel is characterized by its low build hight, the separable corners as well as the low turbulence open testsection with easy access workspace.

Highlights

|

|

Product description

Basic Structure

The WT327 consists of a steel profile welded construction and galvanized sheet metal. The additional painting gives the wind tunnel an attractive appearance and is also protection against corrosion. The wind tunnel has separable corners to enable installation in laboratories that are difficult to access. Access to the inside of the wind tunnel is possible through manholes in all relevant segments.

Drive

The WT327 is driven by a vibration-decoupled axial fan. The fan, which is mounted on spring shock absorbers, is connected to the wind tunnel via canvas flanges. This ensures low-noise system operation and prevents influence on the measuring section. The installation of the fan on cross beams results in optimal freedom in the area of the measuring section.

Flow preparation

In the sieve chamber turbulence is suppressed by two sieves with optimal distance from one another. Furthermore, irregularities in the flow direction of the incoming air are suppressed in a honeycomb straightener. In a nozzle, the nozzle geometry of which corresponds to a 7th order polynomial, the flow is prepared and any turbulence that may be present is suppressed.

Measurement

The measurement in the wind tunnel can be carried out with an open or closed test section.

Open testsection

The measuring table, which is equipped with a wind tunnel scale, has a guide plate to guide the flow into the collecting funnel with little turbulence. The recording of flow characteristics using optical measurement methods, e.g. PIV (Particle Image Velocimetry) or LDA (Laser Doppler Anemometry) is possible without any problems.

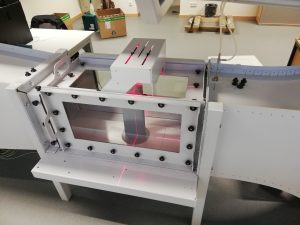

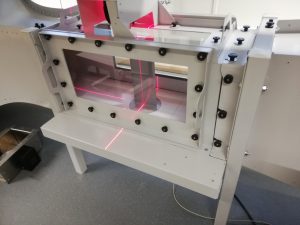

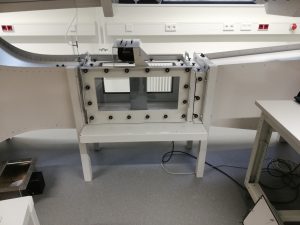

Closed testsection

As a follow-up order, a testsection was delivered and installed for the WT327 at HS Rhein Main. At the customer’s request, the measuring chamber has been equipped with a rotating mechanism on which models can be mounted for measurement. The testsection also has a laser for positioning the models within the testsection.

Highlights

The small corner has two trimming plates to influence the degree of turbulence at constant speed.

Photo series: closed testsection

Characteristics

| Design type | Closed loop |

| Measuring cross section | 400 x 400 mm |

| Measuring length | 600 mm |

| Top speed | 40 m/s |

| Turbulence level | 0,6 % (@50% Windspeed) |

Video