Reference project WT278

Eindhoven University of Technology

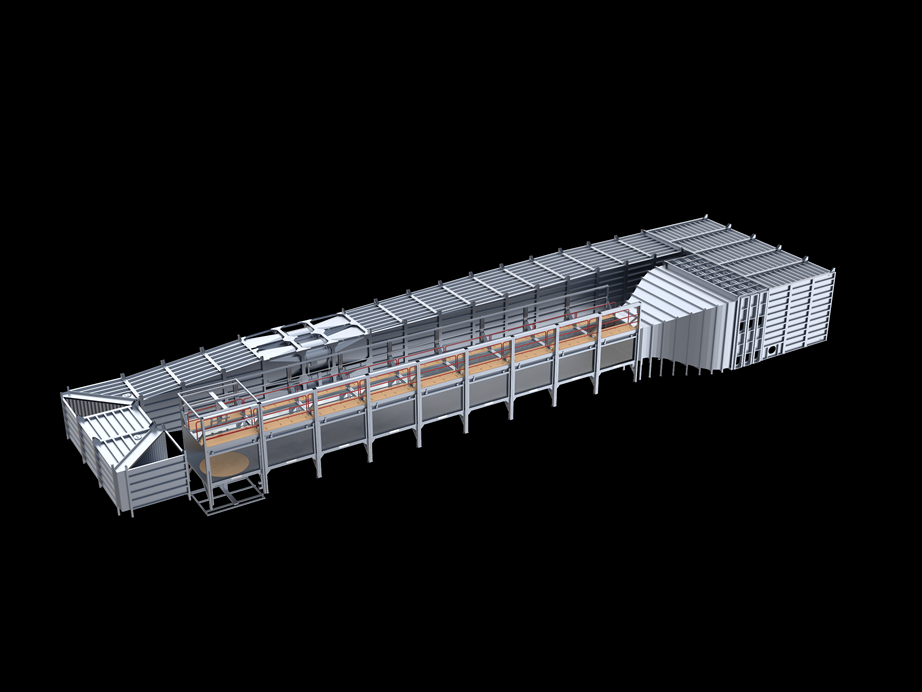

At Eindhoven University of Technology in the Netherlands (contact: Prof. Dr. Bert Blocken), the wind tunnel WT278 was constructed. This wind tunnel is characterized by a large test section, expanding corners, a long diffuser, and a low turbulence level.

Highlights

|

Product Description

Basic Design

The WT278 is built from a welded steel frame construction and galvanized sheet metal. Large inspection hatches in all relevant segments allow easy access to the interior of the wind tunnel.

Drive System

The WT278 is powered by four vibration-isolated axial fans. The fans, mounted on spring vibration dampers, are connected to the wind tunnel via fabric flanges. This setup ensures quiet operation. The fan nacelle and downstream guide vanes are tuned to the fans to generate a swirl-reduced flow.

Flow Conditioning

The long diffuser, whose shallow opening angle prevents flow separation, leads into the large expanding corners. The wind tunnel has a large screen chamber that houses four screens at optimal spacing. These one-piece stainless steel screens are accessible through inspection hatches for easy cleaning. A honeycomb straightener with a length-to-diameter ratio of 8:1 further reduces swirl in the flow. In the nozzle, whose geometry follows a fifth-order polynomial, the flow is conditioned and any remaining turbulence is suppressed.

Measurement Section

Measurements are conducted in a 27-meter-long test chamber with a cross-section of 2 x 3 meters. The chamber consists of 9 segments, each 3 meters long. Each segment is equipped with a side panel and a top panel. The side panels can be lifted by an electric lever mechanism to ensure optimal accessibility. The segments can be individually removed from the test section, allowing the previously closed chamber to be converted into an open test section.

Special Features

At the end of the test chamber is an electrically powered turntable with a diameter of 2.5 meters. For erosion testing, a downstream sandbox and a filter rack are installed on this turntable. This setup enables realistic sand erosion experiments inside the wind tunnel without the need for extensive post-test cleaning.

The WT278 is equipped with three traverse systems:

The top traverse is located above the test chamber segments, allowing measurements through the top panel along the full 27-meter test length.

Below the test chamber is the ground traverse, which enables segment-wise testing using a transparent turntable.

On the side of the test chamber is the side traverse, which carries the LDA system (Laser Doppler Anemometry) and can travel the full 27-meter test section via a rail system.

Directly behind the nozzle, a wind tunnel balance with a capacity of 2 tons is installed. This retractable balance can be driven onto and is then hydraulically lifted into position within the wind tunnel.

Specification

| Design type | Göttinger design, horizontal |

| Test cross-section | 2000 x 3000 mm |

| Test length | 27000 mm |

| max. speed | 30 m/s |

| Turbulence intensity | 0.7 % |

Links

Research laboratory Windtunnel at TU Eindhoven

Homepage Prof. Dr. Blocken